Free SG delivery for orders above S$200!

-

Your shopping cart is empty!

Cart

Free SG delivery for orders above S$200!

WHAT IS JUTE?

Jute is a long, soft, shiny vegetable fiber that can be spun into coarse, strong threads. It is one of the most affordable natural fibers. Jute fibers are composed primarily of the plant materials cellulose and lignin. The industrial term for jute fiber is raw jute. Jute is also called the golden fiber for its color and high cash value.

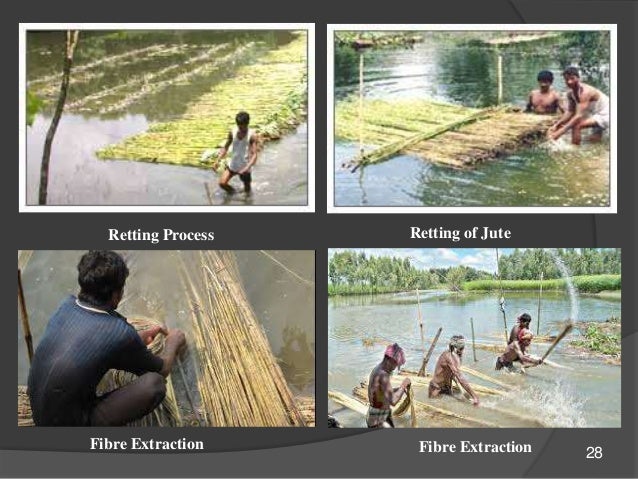

PROCESSING OF JUTE

The fibers are first extracted by retting. The retting process consists of bundling jute stems together and immersing them in slow running water. There are two types of retting: stem and ribbon. After the retting process, stripping begins after the non-fibrous matter is scraped off, then the workers dig in and grab the fibers from within the jute stem.

DYEING COLOR ON JUTE

The desired area of the jute is dipped in the dye bath for around 10 to 15 minutes. The fiber is squeezed inside the bath itself for proper permeation of the dye. The dye can be applied either by hand or with the help of any container. Over-dying should be done on a dyed piece either to hide mistakes or to get the desired effect when the already dyed fabric is completely dry or partially wet and by doing so one can save the dye from being getting contaminated.

MORDANTING

The mordanting should be done immediately before and after the dyeing. The fabric should thoroughly be strained so that the extra dye/mordant is removed before the next process of mordanting/dyeing respectively.

LAMINATION (Optional)

After the jute is woven it is then sent away for lamination. The entire jute roll is laminated with an LDPE lining. The jute is then sent back to the factory. Lamination is optional and it will be performed only if it is requested by the customer as part of the feature in their final product.

CUTTING

After dying the fabric, it goes to the cutting department. Fabric is arranged in layers and cut accordingly to the product patterns.

PRINTING

Screen printing is done on the cut fabric by arranging the fabrics on a large printing table. Water based [Azofree on request] colours are used for printing. After the printing is done the fabric is left to dry. Then it goes for stitching.

STITCHING AND FINISHING

All the parts such as the front, back, gusset, handles, etc are stitched together.

Finished Product- Jute Bags

CHECKING AND PACKING

Once the stitching is done, it is checked for any errors. Then it is mended, rectified, and packed accordingly.